A bottle capping machine is a device used to apply caps to bottles. This type of machine is commonly used in industries such as pharmaceuticals, cosmetics, food and beverage, and chemical manufacturing. The machine typically consists of a hopper for holding the caps, a capping head for securing the cap to the bottle, and a mechanism for moving the bottles through the capping process. Some bottle capping machines are designed to handle a specific type of cap or bottle, while others are more versatile and can be adjusted to accommodate different sizes and shapes. Bottle capping machines are typically automatic, allowing for high-speed production and efficient operation.

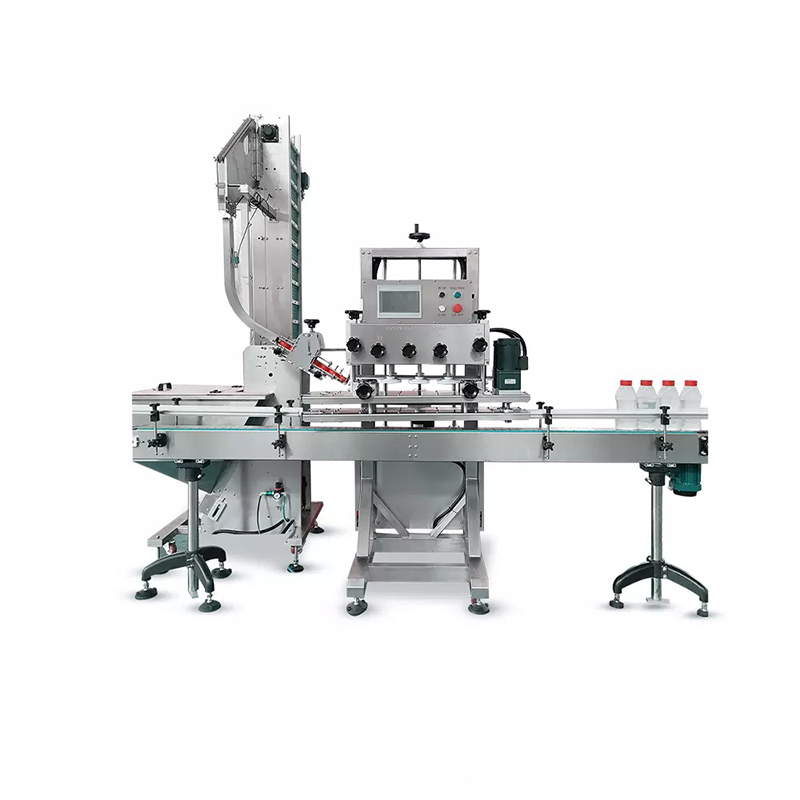

Automatic 6 Wheels Spindle Capping Machine

The automatic spindle capper is almost a universal capper, it is sutiable for capping screw caps, flip flop caps, spray caps, drops caps, metal caps, twist off caps. The capping is by 6 wheels spindle, and driven by motors, and the driven system can be servo, for torque adjustable. We update this capper for some generation, and now it is more flexiable and efficient. adjust for different types of containers and caps, tool is free, most of the adjustment can be completed on HMI.

- We adopt the mode of ‘one motor controls one capping wheel’, which can ensure the machine to work stably and keep consistent torque under long term working condition.

- The clamping belts can be adjusted separately, which allow the machine to be suitable for capping bottles with various heights and shapes.

- If you choose the optional cap guiding system together with the machine, it will then also fit for pump caps.

- The convenient construction adjustment system is equipped with precise ruler and counter.

- The mainframe can be lifted and descended automatically by a motor.

| NAME MODEL | Automatic linear spindle capping machine |

| Capacity | 0~200b/m(subject to bottles and cap size) |

| Bottle and cap diameter | Φ10~120 subject to samples |

| Bottle Height | 40~460mm |

| Spindle capping machine dimension | L1060*W896*H1620mm |

| Voltage | AC 220V 50Hz |

| Power | 1600W |

| Weight | 500kg |

| Cap Feed system | Elevator feeder |

| Dimension | L880×W1000×H2600mm |

Automatic 4 Wheels Bottle Capping Machine

A four-wheel capping machine is a type of bottle capping machine that uses four wheels to apply caps to bottles. This type of capping machine is typically used for medium-speed production and is capable of applying caps to bottles at a moderate rate. The four wheels of the capping machine work together to secure the cap to the bottle, ensuring that the cap is properly applied and the bottle is sealed properly. Four-wheel capping machines are commonly used in industries such as pharmaceuticals, cosmetics, and food and beverage production, where the need for medium-speed capping is required.

- Automatic cap feeding system, vibrating tray.

- No tools requirements for different size adjust for capping system.

- Output meet the filling machine, but max 30 bottles/ min.

- No bottle No capping.

- Control panel with touch screen. capping programs saving.

- Machine’s body of SS 304.

| Production Capacity | 12-40BPM depending on bottle sizes and shapes |

| Bottle Height | Up to 460MM |

| Cap Diameter | Up to 70MM |

| Voltage/Power | 220VAC 50/60Hz 450W |

| Driven way | Motor with 4 wheels |

| Interface | DALTA Touch Screen |

| Spare Parts | Capping Wheels |

Automatic ROPP Capping Machine

- The machine integrates automatic cover, upper cover and automatic screw cap. The production speed is fast, the efficiency is high, and the operation is stable and reliable.

- Applicable bottle shape has round, square, various shapes, etc., and has strong applicability;

- the replacement of different specifications of the bottle, the lid is simply adjusted, easy to operate;

- the use of world-renowned brands of electrical and pneumatic components, low failure rate, stable and reliable performance, long service life.

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-5000 | |||

| Production capacity | Bottle/h | 1000-3000pcs(Depends on filling volume) | |||

| Quantitative error | % | 100-1000ml:≤±2% , 1000-5000ml:≤±1% | |||

| Voltage | V | AC220V 380V ±10% | |||

| Consumed power | KW | 1.5 | 1.5 | 1.5 | 1.5 |

| Air pressure | MPA | 0.6-0.8Mpa | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Automatic Press Snap Capping Machine

It is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals, etc.

The machine use the straight line into the bottle, automatically arrange caps, sleeving caps, caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly. The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

- This machine is made of stainless steel plate, it is reliable.

- The principle of synchronous chain plate cover can be used to cover all kinds of plastic anti fake cover without any scratch.

- The utility model has the advantages of novel structure, few faults, long service life and reliable operation.

- Stepless variable frequency motor speed control, suitable for a wide range of bottle type.

| Model | AM-PC |

| Applied bottle range | 100ml-1000ml 1000ml-5000ml |

| Applied cap size | Dia: 12-120mm |

| Yield of capping | >99% |

| Power Supply | 220V 50HZ |

| Power Consumption | <2KW |

| Air Pressure | 0.4-0.6Mpa |

| Speed Control | Frequency Convertion |

| Single machine noise | <=70Db |

| Weight | 850kg |

| Dimension(L*W*H) | 2000x1100x1800(mm) |

| Production Capacity | 5000-7200 bottles/h |

Pick and Place Bottle Capping Machine

A pick and place bottle capping machine is a type of bottle capping machine that uses a pick and place mechanism to apply caps to bottles. This type of capping machine typically consists of a hopper for holding the caps, a pick and place mechanism for picking up the caps and placing them onto the bottles, and a mechanism for moving the bottles through the capping process. The pick and place mechanism is typically highly precise, allowing the caps to be placed onto the bottles with a high degree of accuracy. This type of capping machine is commonly used in industries such as pharmaceuticals, cosmetics, and food and beverage production, where the need for precise capping is essential.

AMPACK built two types of pick and place capping machine, one is the linear types and another is rotary bottle capper. No matter which types, it containes two main parts, one is the automatic pick cap device, and another one is the capping station.

- The rotary one, bottle working on a star wheels, for different size of bottle need changeover the star wheel, the changeover no tools required, takes less than 5 mins, we adapt flexiable slot, just take off the wheels than replace another new one.

- The linear type is more flexiable, no need any changeover parts except the capping heads, speed is more efficient than the rotary one.

- Small vial less 100ml rotory one is more suitable, linear type is mostly application for daily checmicals, Food industry.

- Both of the two pick capper driven by servo motor, torque is adjustable.

- PLC control and also emotion controller for option for a high speed non stop working.

| Model | AM-PC-1/AM-LC-1 | AM-PC-2/AM-LC-2 |

| Capacity | 1800 b/h and 2400b/h | 3600 b/h and 4200b/h |

| Suitable cap | Screw cap or snap cap | |

| Yield of cap | 99.9% | |

| Dimension | 2000x1000x1500mm | 2200x1000x1500mm |

| Capping head | 1 | 2 |

| Press head | 1 | 2 |

| Power consumption | 2KW | 3KW |

| Weight(kg) | 600kgs | 800kgs |

A bottle capping machine is a piece of equipment that is used to apply caps onto bottles or other containers. This type of machine is commonly used in industries such as pharmaceuticals, cosmetics, and food and beverage production. Bottle capping machines are designed to be efficient, reliable, and easy to use, and they come in a variety of different types and sizes to suit different production needs.

In this ultimate guide, we will discuss the different types of bottle capping machines, the features and benefits of each type, and the factors to consider when choosing a bottle capping machine for your business. We will also provide some tips for maintaining and troubleshooting your bottle capping machine, as well as some potential applications and industries that can benefit from using a bottle capping machine.

Types of Bottle Capping Machines:

There are several different types of bottle capping machines, each with its own unique features and benefits. The type of capping machine that is right for your business will depend on factors such as the size and type of bottles you are using, the type of caps you are applying, and the speed and efficiency of your production line.

Some common types of bottle capping machines include:

Spindle capping machines:

Spindle capping machines are the most common type of capping machine. They use a spindle, which is a threaded rod, to screw the cap onto the bottle. Spindle capping machines are often used for screw-on caps, and they can handle a wide range of cap sizes and shapes.

Snap capping machines:

Snap capping machines use a mechanical arm or other mechanism to push the cap onto the bottle. The cap is designed to snap onto the bottle, securing it in place. Snap capping machines are often used for snap-on caps, and they can handle a wider variety of cap sizes and shapes than spindle capping machines.

Rotary capping machines:

Rotary capping machines use a rotating mechanism to apply the cap onto the bottle. The cap is placed onto the bottle by the machine, and then the bottle is rotated to secure the cap in place. Rotary capping machines are often used for screw-on or snap-on caps, and they are typically faster and more efficient than other types of capping machines.

Chuck capping machines:

Chuck capping machines use a chuck, which is a mechanical device that grips the cap, to apply the cap onto the bottle. The cap is placed onto the chuck by the machine, and then the chuck is used to secure the cap onto the bottle. Chuck capping machines are often used for screw-on or snap-on caps, and they are typically more accurate and precise than other types of capping machines.

Features and Benefits of Bottle Capping Machines:

Bottle capping machines offer a range of features and benefits that make them an essential part of any production line. Some of the key features and benefits of bottle capping machines include:

Efficiency and speed:

Bottle capping machines are designed to be efficient and fast, allowing you to cap bottles quickly and accurately. This can help you to increase the speed of your production line, reducing bottlenecks and improving overall productivity.

Precision and accuracy:

Bottle capping machines are designed to be precise and accurate, ensuring that the cap is properly applied to the bottle every time. This can help to prevent issues such as leaks or spills, and it can also ensure that the cap is securely fastened and will not come off during handling or transportation.

Versatility and flexibility:

Bottle capping machines are designed to be versatile and flexible, allowing you to use them with a wide range of bottle sizes, cap sizes, and cap types. This means that you can use the same capping machine for different products, reducing the need for multiple machines and simplifying your production process.

Easy to use and maintain:

Bottle capping machines are designed to be easy to use and maintain, with user-friendly controls and simple maintenance procedures. This means that you can train your staff to use the capping machine quickly and easily, and you can also perform regular maintenance to ensure that the machine is always in good working order.

Durability and reliability:

Bottle capping machines are designed to be durable and reliable, with high-quality components and construction. This means that you can count on your capping machine to perform consistently, even with heavy use and in demanding environments.

Factors to Consider when Choosing a Bottle Capping Machine:

When choosing a bottle capping machine for your business, there are several factors that you should consider. These factors will help you to select the right type of capping machine for your needs, and ensure that you get the best possible performance and value for your investment. Some of the key factors to consider when choosing a bottle capping machine include:

Bottle and cap sizes:

The first thing to consider when choosing a bottle capping machine is the size and shape of the bottles and caps that you will be using. Different capping machines are designed to handle different sizes and shapes of bottles and caps, so it is important to choose a machine that is compatible with your containers.

Cap type:

Another important factor to consider when choosing a bottle capping machine is the type of cap that you will be using. Some capping machines are designed to handle specific types of caps, such as screw-on caps or snap-on caps, while others are more versatile and can handle a wider range of cap types.

Production speed and capacity:

The speed and capacity of your bottle capping machine will depend on the size of your production line and the amount of bottles that you need to cap. You should choose a capping machine that can handle the speed and volume of your production, to ensure that you get the best possible performance and efficiency.

Budget and cost:

When choosing a bottle capping machine, it is important to consider your budget and the total cost of the machine. Different capping machines have different price points, and you should choose a machine that fits within your budget and provides good value for money.

Maintenance and support:

Finally, you should consider the maintenance and support that is available for your bottle capping machine. Look for a machine that is easy to maintain, and choose a manufacturer or supplier that provides good customer support and technical assistance.

Tips for Maintaining and Troubleshooting your Bottle Capping Machine:

Once you have chosen and installed your bottle capping machine, there are a few steps that you can take to ensure that it stays in good working order and continues to perform at its best. Some tips for maintaining and troubleshooting your bottle capping machine include:

Perform regular maintenance:

Your bottle capping machine will need regular maintenance to ensure that it continues to operate correctly. This may include cleaning the machine, checking and replacing parts, and lubricating moving parts. Follow the manufacturer's instructions for regular maintenance, and perform it on a regular schedule to keep your capping machine in good working order.

Keep the machine clean:

Keeping your bottle capping machine clean is important for maintaining its performance and longevity. Clean the machine regularly, using a soft cloth and a mild cleaning solution. Avoid using abrasive cleaners or solvents, as these can damage the machine's components.

Check and replace worn parts:

Over time, the components of your bottle capping machine may wear out or become damaged. Regularly check the machine for worn or damaged parts, and replace them as needed. This will help to ensure that the machine continues to operate correctly and efficiently.

Troubleshoot and diagnose problems:

If you encounter any problems with your bottle capping machine, try to troubleshoot and diagnose the issue yourself before contacting the manufacturer or supplier for assistance. Check the machine's controls, settings, and components, and try to identify the source of the problem. If you are unable to diagnose the problem, contact the manufacturer or supplier for technical support.

Potential Applications and Industries for Bottle Capping Machines:

Bottle capping machines are used in a wide range of industries and applications, including:

Pharmaceuticals:

In the pharmaceutical industry, bottle capping machines are used to apply caps onto bottles of medication and other health products. This helps to ensure that the caps are securely fastened, preventing leaks or spills and protecting the contents of the bottle.

Cosmetics:

In the cosmetics industry, bottle capping machines are used to apply caps onto bottles of makeup, skincare products, and other cosmetics. This helps to protect the products and prevent leaks or spills, ensuring that they remain fresh and effective.

Food and beverage production:

In the food and beverage industry, bottle capping machines are used to apply caps onto bottles of drinks, sauces, and other food products. This helps to keep the contents of the bottle fresh and prevents leaks or spills, ensuring that the products are safe and appealing to consumers.

Chemical production:

In the chemical industry, bottle capping machines are used to apply caps onto bottles of chemicals, cleaners, and other products. This helps to prevent leaks or spills, and it also helps to protect workers and the environment from exposure to hazardous substances.

Conclusion:

A bottle capping machine is an essential piece of equipment for any business that needs to apply caps onto bottles or other containers. Bottle capping machines come in a variety of types and sizes, and they offer a range of features and benefits that make them efficient, reliable, and easy to use. By considering the factors discussed in this guide, you can choose the right bottle capping machine for your business, and enjoy the many benefits that it has to offer.

Related Products

What Is Liquid Filling?

What Is Liquid Filling? What is a Bottom Up Filling Machine?

What is a Bottom Up Filling Machine? Liquor Bottle Filling Machine: The Ultimate Guide

Liquor Bottle Filling Machine: The Ultimate Guide Peanut Butter Filling Machine

Peanut Butter Filling Machine Cream Filling Machine

Cream Filling Machine Hot Sauce Bottling Machine: The Ultimate Guide

Hot Sauce Bottling Machine: The Ultimate Guide Juice Filling Machine

Juice Filling Machine What Is Filling And Capping Machine?

What Is Filling And Capping Machine? Quantitative Filling Machine: The Ultimate Guide

Quantitative Filling Machine: The Ultimate Guide Salsa Filling Machine: The Ultimate Guide

Salsa Filling Machine: The Ultimate Guide