In most packaging lines, the sequence of operations begins with bottle preparation. This involves organizing and placing the bottles on a conveyor for transport to a cleaning station. Bottle rinsing machines are used to evacuate dust and other small particles from glass, metal, and plastic bottles cleaning them prior to bottling. These contaminants often accumulate in the bottle during shipping or storage, and must be removed to provide a cleaner bottle.

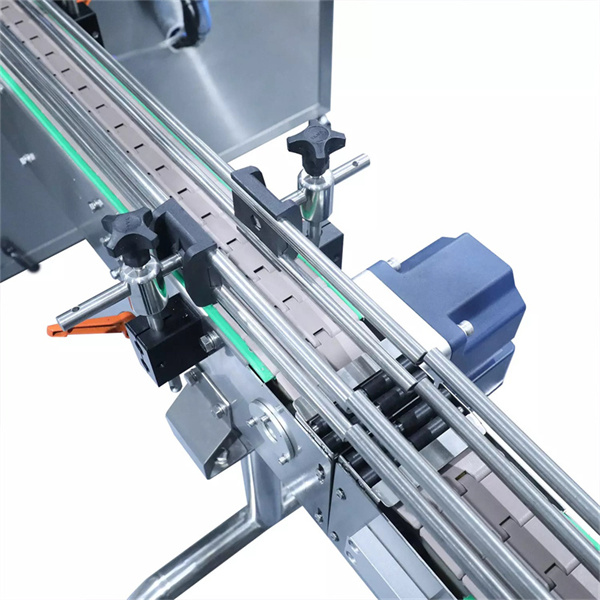

Our bottle washing machines are designed with a focus on flexibility, versatility and simplicity. The mechanical components of our bottle cleaning machine allows many container shapes and sizes to be run with simple changeover, using few or no change parts. The advanced touch screens PLC controls on our rinsers provide the ability to store multiple programs in the PLC controller, further decreasing changeover times. Bottle washers, cleaners, and container indexing settings are easily programmed and saved with our rinsers automatic setup mode, enabling the bottle cleaners changes to be made quickly and effortlessly.

Automatic Bottle Water Risning Machine

1. Production capacity: Customized 4,6,8,10,12,14,16 heads

2. Power supply: 380V/220V 50Hz

3. Machine power: 2KW

4. Air pressure: 0.6~0.8Mpa clean air

5. Bottle rinse medium: filter water, one time water washing, compress air.

6. Program control: PLC + touch screen interface.

| Bottle rinse medium | filter water, one time water washing, compress air |

| Program control | PLC + touch screen interface |

| Production capacity | Customized 4,6,8,10,12,14,16 heads |

| Power supply | 380V/220V 50Hz |

| Machine power | 2KW |

| Air pressure | 0.6~0.8Mpa clean air |

| Filling speed | 1000-5000BPH |

| Keywords | flip type |

| Material | 304 Stainless Steel |

| Suitable for | Many bottle types of industries |

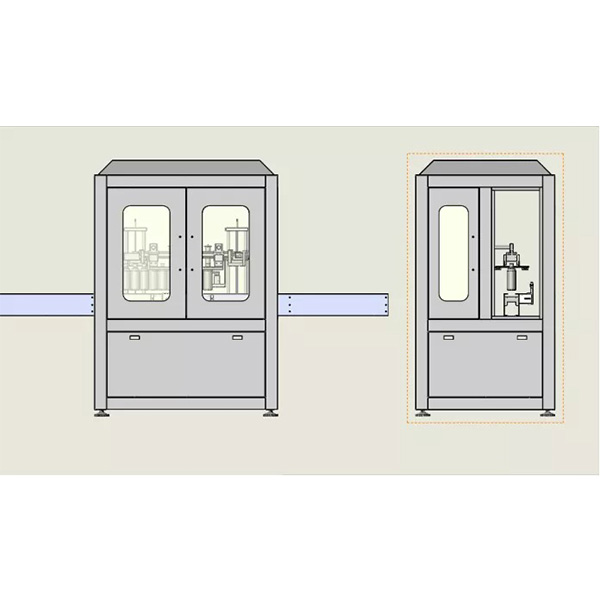

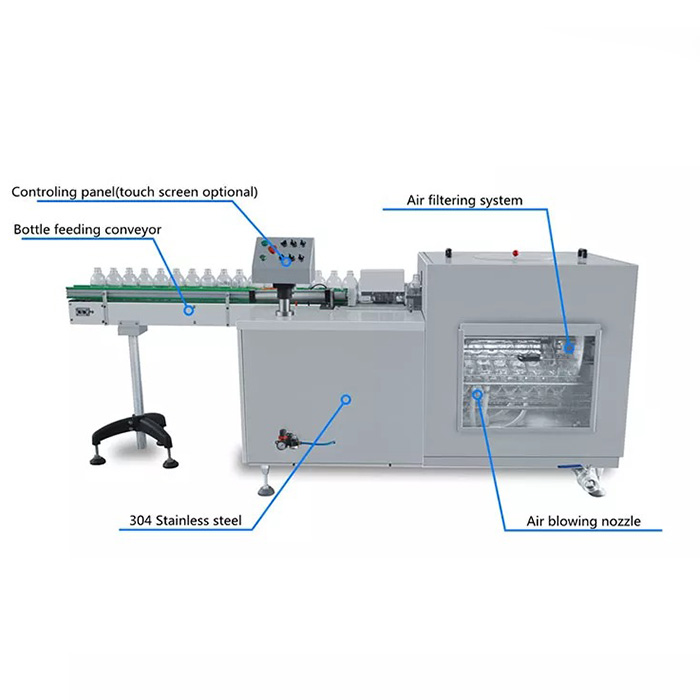

Linear Automatic Bottle Air Washing Machine

Bottle rinsers can work with a wide range of different container shapes, sizes and materials, including both glass and plastic. It is an automatic cleaning device for different kind of bottles, which has increased the labor productivity greatly and avoid thecross contamination and microbiological pollution caused by manual cleaning.

| Output | 20-160bottle /min |

| Bottle spec.(ml) | 15-500ml |

| Voltage(V)/(Hz) | 220V AC60/50HZ |

| Power | 0.3kw |

| Air pressure | 0.5(mpa) |

| Air supply | 0.8(m3/h) |

| Overall Dimension | 1600*700*1700 |

| Weight(kg) | 320kg |

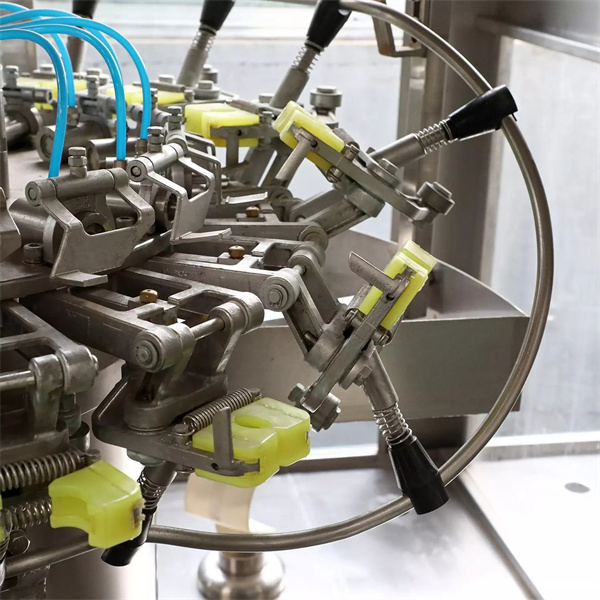

Rotary Bottle Air Jet Washing Cleaning Machine

Machine Feature:

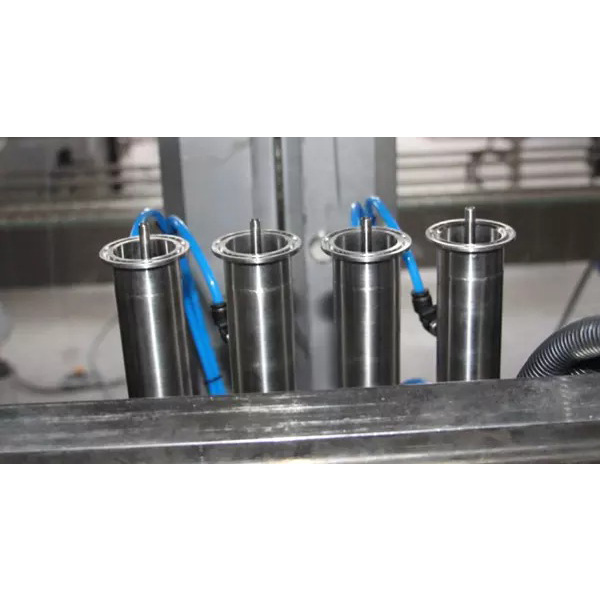

1.This series of machines adopts flexible and strong mechanical hand grip bottle, bottle turning, washing, bottle control, turnover reset, bottle out and so on, and fully automated production has been realized.

2.The dial mechanism is automatically inserted into the dialing bottle, and a protective device is arranged at the lower part of the incoming and outgoing dial, and the machine is automatically stopped when the bottle is clamped, so as to effectively protect the host machine and reduce the damage of the glass bottle.

3. Continuous washing, and synchronous washing of the outer wall of the bottle, washing bottles clean, no water droplets, flushing effect is stable and reliable.

4.It can be used in conjunction with filling machines and other equipment. The machine has the advantages of simple structure and high cleaning rate

Output capacity: 500BPH-8000BPH (different heads can be customized)

Automatic Drum Bottle Washing Cleaning Machine

1. This machine is a bottle cleaning equipment in the bottle liquid filling production line, which is mainly used to clean the dust inside the plastic bottle.

2. After the bottle into the gas wash box flip 180 degrees, the jet into the bottle for showering, after the completion of flip 180 degrees after the air wash tank. Gas inside the exhaust box by a dedicated centrifugal fan sucked out of the room.

This Machine is suitable for automatic various glass or plastic bottles simple cleaning before filling. Can connected with bottles filling machine to combine whole packing line.

| Bottles Washing Speed | 10~120 bottles/min |

| Suitable bottle size | 1~1000ml, customized |

| Return water flow | 2m3/h, depends |

| Return water pressure | 0.3~0.5MPa |

| Injection water consumption | 1m3/h Pressure |

| Injection water pressure | 0.2 ~ 0.25MPa |

| Ultrasonic power | 2kw depends |

| Machine weight | Customized |

| Power supply | 220V/380V accept customization |

Containers may collect dust or debris from the manufacturing process of the bottle, during shipping or even during storage as they wait to be used on a packaging line. For a number of different industries, ensuring that containers are clean before the introduction of product can be a very important step. Food and beverage companies and other industries that produce edible or consumable products, for example, would not want their products to become contaminated during the packaging process. Other industries may have their own reasons for cleaning containers prior to the filling process. Liquid Packaging Solutions provides a number of bottle rinsing and washing machines that can clean bottles and also assist in keeping the entire packaging process sanitary.

Probably the most popular container cleaning machine is the automatic inverting air rinsing machine. The descriptive name tells you almost everything you need to know about this piece of equipment. Using a conveyor and indexing system, the auto air rinser moves containers into position under the rinse nozzles. Once in place, the containers will be clamped and inverted over a rinse basin. The nozzles blast the inside of the containers with clean air, loosening debris and allowing it to be released to the rinse basin. Rinsed containers are then returned to the conveyor, unclamped and sent to the filling machine!

Automatic rinsing machines can also be manufactured to use water or other liquid to clean containers, or even to use a combination of air and water. The key benefit to the air rinser is the lack of waste product when water, packager product or other liquid is used to clean bottles.

Five Reasons Packagers Use Automatic Bottle Rinsing Machines

1. Helps Keep the Packaging Process Sanitary

First and foremost, rinsing and washing machines help to keep the packaging process sanitary. Even if all other equipment is manufactured as sanitary machinery, the bottles or other containers introduced into the process can contaminate a product. Dust, debris and other material may be left behind during production of a container, may accumulate during the shipping of the container or could even build up sitting in a warehouse waiting to be used. Incorporation of a rinsing machine protects the integrity of the a sanitary packaging line.

2. Required for Certain Products or Industries

Container cleaning equipment is essentially required for industries such as Food & Beverage, Pharmaceutical, Nutraceutical and other areas where products are ingested or consumed. Certain industries will be regulated by rules or laws that will require a product to be free from contaminants, in order to protect the consumer. If you belong to one of these industries, a rinser, washer or other cleaning machine may not only be desirable, but may be a necessity.

3. Versatile Machinery

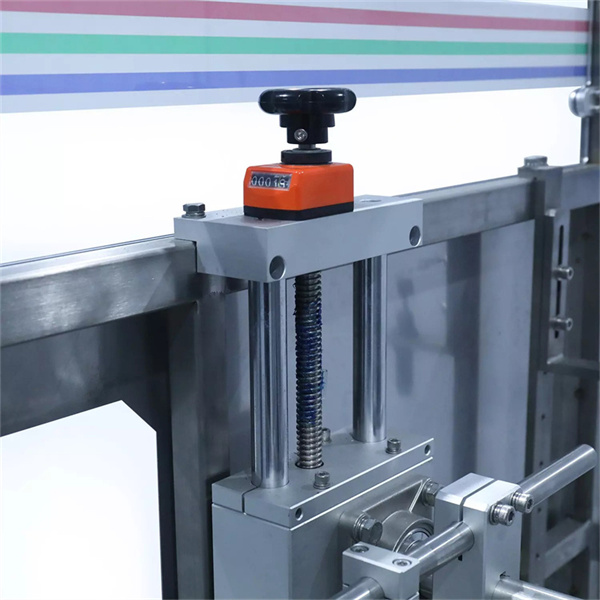

Container cleaning equipment, like filling machines, can normally handle a range of container shapes and sizes. Simple adjustments to clamps, rails and other components of the cleaning machinery allows quick and easy bottle changeover. In addition, these machines can be manufactured to handle both glass and plastic containers, as well as clean inside the bottle, outside the bottle or both, if desired.

4. Easy To Operate

As noted above, adjustments to the container cleaning equipment are normally quick and easy, achieved without the use of tools. In addition, automatic rinsing and cleaning machines will almost always use a PLC with a touchscreen operator interface. Very similar to liquid fillers, the operator interface allows the user of the machine to simply input delay and duration times on a single screen. In most cases, a recipe screen can also be used, meaning the correct settings can be saved and recalled in a quick and simple manner.

5. Speed

As with all automatic packaging equipment, automatic container cleaning equipment will help speed up the packaging process. Imagine rinsing or washing every bottle or container by hand before sending it to the filler, capper, labeler or other packaging equipment. Automatic equipment speeds up the process by using multiple rinse heads and continually cycling bottles through the machine to keep pace with the other packaging equipment.

Related Products

Dropper Bottle Filling Machine: The Ultimate Guide

Dropper Bottle Filling Machine: The Ultimate Guide What Is Gravity Filling Machine?

What Is Gravity Filling Machine? Peanut Butter Filling Machine

Peanut Butter Filling Machine Industrial Bottle Filling Machine: The Ultimate Guide

Industrial Bottle Filling Machine: The Ultimate Guide Batter Filling Machine: The Ultimate Guide

Batter Filling Machine: The Ultimate Guide Which is The Best System of Filling?

Which is The Best System of Filling? Paste Filling Machine

Paste Filling Machine What Is Filling Volume?

What Is Filling Volume? How Does A Tube Filling Machine Work?

How Does A Tube Filling Machine Work? What is Peristaltic Pump Filler?

What is Peristaltic Pump Filler?