Introduction

Definition of Pressure Sensitive Labelers:

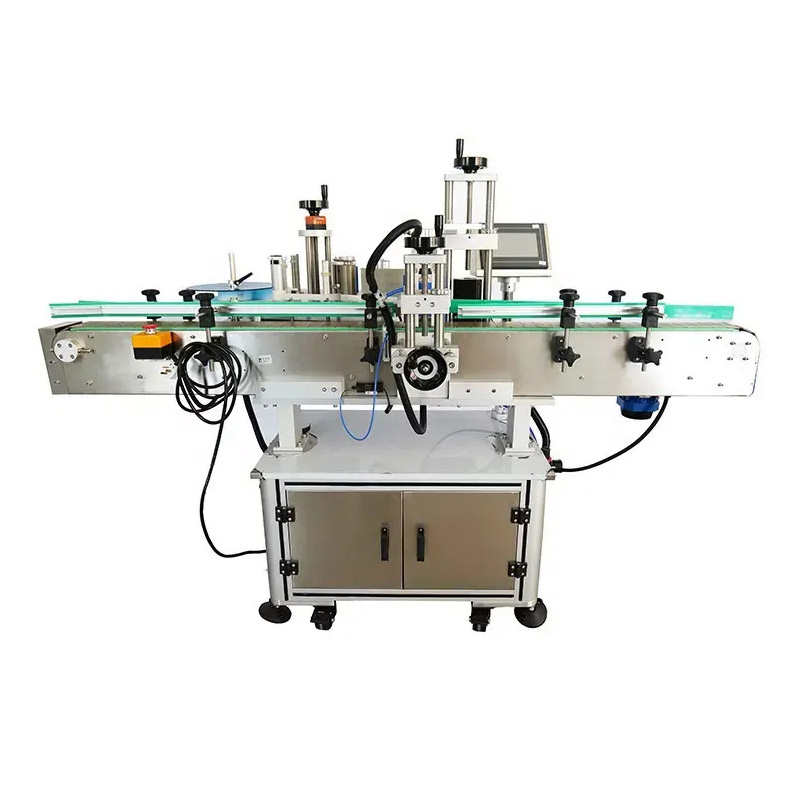

Pressure sensitive labelers are machines used in liquid packaging operations to quickly and accurately apply labels to containers. These labelers use pressure-sensitive adhesive to stick the label to the container, making it easy to apply and remove.

Importance of Pressure Sensitive Labelers in Liquid Packaging Operations:

Pressure sensitive labelers play a critical role in modern liquid packaging operations. They provide a professional and polished look to your containers, making them more appealing to consumers. They also help you keep track of your inventory, providing important information such as expiration dates, product names, and other important details.

Overview of the Different Types of Pressure Sensitive Labelers:

There are two main types of pressure sensitive labelers: roll-fed labelers and sheet-fed labelers. Roll-fed labelers are best for high-volume operations, while sheet-fed labelers are best for low-volume operations or for applying unique or specialized labels. In the next section, we will explore the differences between these two types of labelers in more detail.

Types of Pressure Sensitive Labelers

Roll-fed Labelers

Advantages: Roll-fed labelers are ideal for high-volume operations, as they can quickly apply large quantities of labels to your containers. This makes them perfect for companies that produce large quantities of liquid products. Additionally, roll-fed labelers are relatively easy to use and maintain, making them a popular choice for many businesses.

Best Uses: Roll-fed labelers are best used for high-volume operations in industries such as food and beverage, cosmetics, and chemicals. They are also suitable for businesses that need to apply labels to round or cylindrical containers.

Sheet-fed Labelers

Advantages: Sheet-fed labelers are ideal for low-volume operations, or for applying unique or specialized labels. This type of labeler allows you to apply individual labels to your containers, giving you greater control over the labeling process. Additionally, sheet-fed labelers are more flexible than roll-fed labelers, making them suitable for labeling containers of various shapes and sizes.

Best Uses: Sheet-fed labelers are best used for low-volume operations or for applying unique or specialized labels. They are also suitable for businesses that need to apply labels to square or rectangular containers. Industries such as wine and spirits, personal care, and pharmaceuticals often use sheet-fed labelers.

Choosing the Right Pressure Sensitive Labeler

Size and Shape of Containers:

One of the most important factors to consider when choosing a pressure sensitive labeler is the size and shape of your containers. Roll-fed labelers are better suited for round or cylindrical containers, while sheet-fed labelers are better suited for square or rectangular containers. Consider the size of your containers and the type of labels you need to apply when making your decision.

Speed and Accuracy:

Another important factor to consider when choosing a pressure sensitive labeler is speed and accuracy. If you are operating a high-volume operation, you will need a labeler that can keep up with demand. On the other hand, if you are operating a low-volume operation, you may not need a labeler that is as fast. Consider your production requirements when choosing a pressure sensitive labeler.

Cost and Maintenance Requirements:

Finally, you should consider the cost and maintenance requirements of the labeler. Some labelers are more expensive than others, but may be worth the investment due to their speed, accuracy, and durability. Make sure to factor in the cost of maintenance when choosing a labeler, as well. Consider the long-term costs of owning and operating the labeler before making a decision.

Tips for Getting the Most Out of Your Pressure Sensitive Labeler

Proper Set Up and Maintenance:

To get the most out of your pressure sensitive labeler, it is important to set it up properly and maintain it regularly. Make sure to follow the manufacturer's instructions and guidelines for setting up and using your labeler. Regular maintenance will keep your labeler running smoothly and extend its lifespan.

Selecting the Right Labels:

Another key to getting the most out of your pressure sensitive labeler is selecting the right labels. Choose labels that are specifically designed for use with your labeler, and make sure that they are of the right size, shape, and adhesive strength for your containers. Using the right labels will ensure that they stay in place and do not fall off over time.

Maintaining Consistent Production Speed:

Finally, it is important to maintain consistent production speed when using your pressure sensitive labeler. This will help you to achieve the best results and minimize the risk of errors. If you are using a high-volume labeler, make sure that you are able to keep up with demand and maintain a consistent speed. If you are using a low-volume labeler, make sure that you are taking the time to apply labels accurately and carefully.

Conclusion

The Importance of Pressure Sensitive Labelers:

Pressure sensitive labelers play an important role in the packaging process for many businesses, particularly in industries such as food and beverage, cosmetics, and chemicals. They allow you to easily apply labels to your containers, providing important information such as product name, ingredients, and instructions.

The Right Labeler for Your Business:

Choosing the right pressure sensitive labeler is critical to ensuring the success of your business. Consider factors such as the size and shape of your containers, production speed and accuracy requirements, and cost and maintenance requirements when making your decision.

Tips for Success:

Finally, it is important to follow best practices when using your pressure sensitive labeler. Make sure to set it up properly, maintain it regularly, use the right labels, and maintain consistent production speed. With the right pressure sensitive labeler and the right approach, you can ensure that your labeling process runs smoothly and effectively.