A bottle unscrambler is a machine used to feed bottles onto production lines in the bottling industries. Many designs are available, but their purpose is the same, feed bottles automatically at high speeds eliminating the expensive, inefficient manual labor of this process.

AMPACK manufactures a full line of Bottle Unscramblers to sort, organize, orient and deliver bottles or containers into a single, upright and orderly fashion, right onto your production line. Whether your container is large or small, your production line is fast or slow, or your product is pharmaceutical, food, beverage, cosmetic, or chemical, AMPACK has a low or high speed bottle unscrambling system to help maximize your production line efficiency.

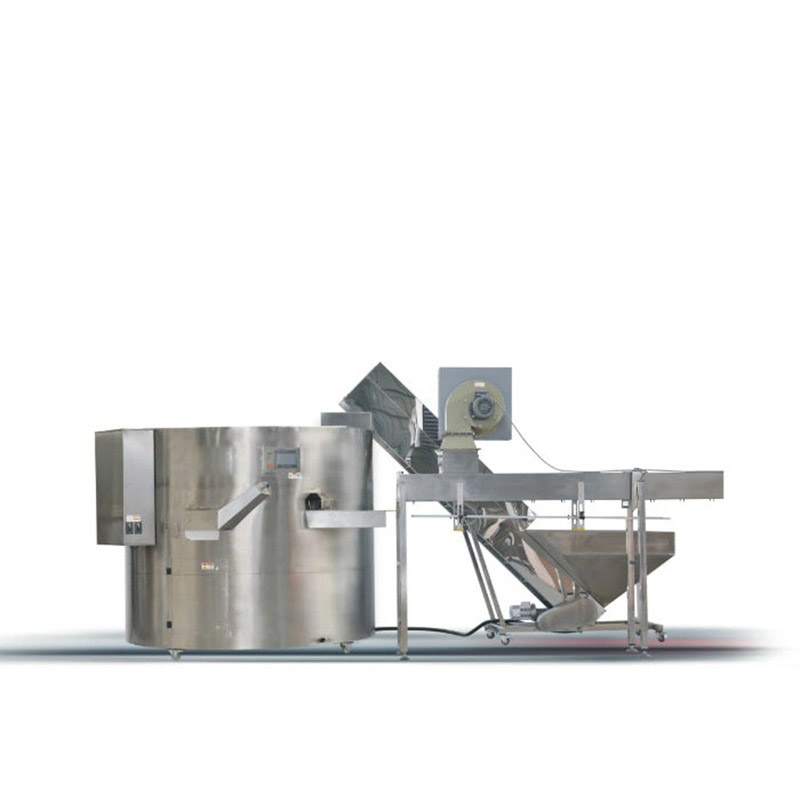

High Speed Pet Bottle Unscrambler Machine

According to the user requirements, the bottle types can be flexibly altered, convenient and rapid.

It adopts the structure of innovative push-and-hold bottle unscrambler, maximally reducing wearing of the bottle body.

The frame is made of excellent stainless steels; and other parts, non-toxic and endurable materials.

The adopted key parts of the electric and pneumatic systems are famous brands.

The whole process is controlled by PLC, so the machine has a low fault rate but a high reliability.

| Model | AM-LPJ1800 | AM-LPJ2000 | AM-LPJ2200 | AM-LPJ2400 | AM-LPJ25000 | |

| Product speed | (b/h) | 8000 | 12000 | 16000 | 20000 | 24000 |

| Power | (kw) | 3 | 3 | 3 | 3.5 | 3.5 |

| Voltage | (v) | 220 | 220 | 220 | 220 | 380 |

| Suitable for bottle diameter | (mm) | ø28-125 | ø28-125 | ø28-125 | ø28-125 | ø28-125 |

| Dimension | (mm) | ø1820x1800H | ø2000x1800H | Φ2200×2300H | Φ2400×2300H | Φ2600×2300H |

| Weight | (kg) | 3250 | 3500 | 4200 | 4600 | 5000 |

Bottle Sorting Turntable Feeding Table Machine

| Model | AM-LP800 | AM-LP1000 | ||

| Turntable Diameter | 800mm | 1000mm | ||

| Suitable Bottle Diameter | 20-100mm | |||

| Suitable Bottle Height | 30-120mm | |||

| Working Speed | 40-60 bottles/min(depends on bottle size) | |||

| Motor Power | 0.2KW | |||

| Power Supply | 220V/50-60HZ | |||

| Net Weight | 109.5kg | 135kg | ||

| Package Size | 115*100*132cm | 135*131.5*123.5cm | ||

| Gross Weight | 155kg | 180kg | ||

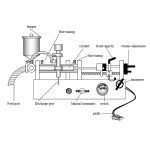

Box Type Bottle Sorting Machine For Plastic Bottle

It can be connected with equipment such as bottle washing machine, filling and capping machine and labeling machine. It is widely used in pharmaceutical, food, chemical and other industries. In order to improve the automation degree, equipped with a storage bin and an automatic bottle feeding mechanism.

| Items | Parameters |

| Capacity | 80~120BPM(adjustable) |

| Power supply | 220V/50Hz |

| Power consumption | 0.5kw |

| Machine weight | 200kg |

| Overall size | 1500×1200×1200(mm) |

Linear Automatic Bottle Unscrambler Machine

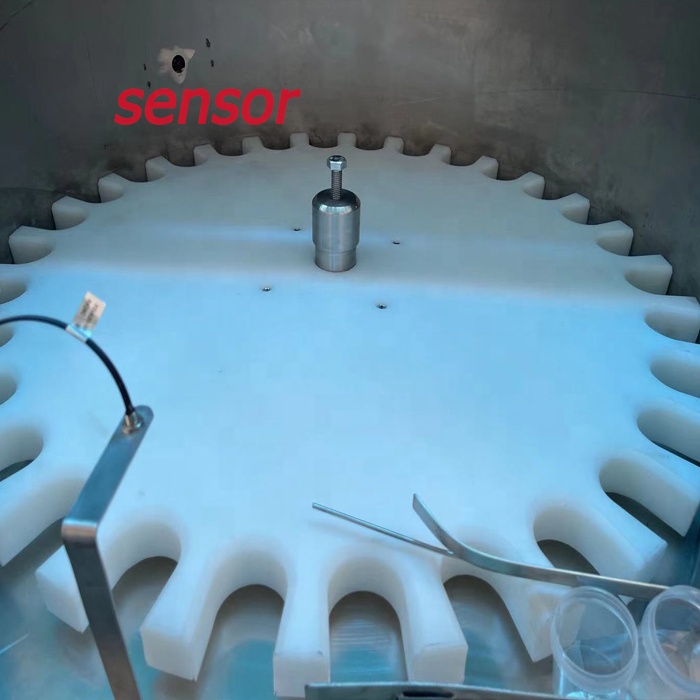

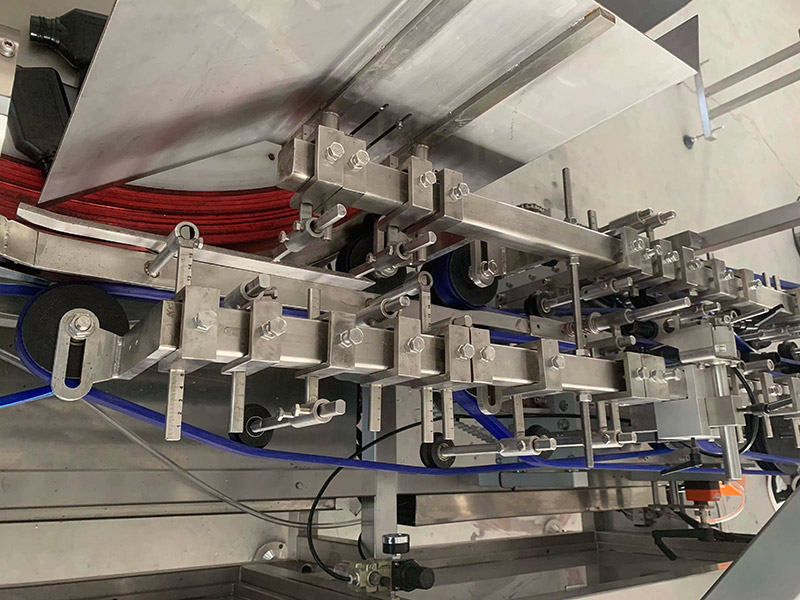

The Automatic Bottle Unscramble is used for sorting and feeding bottles for the filling line automatically. It is making up of bottle elevator, bottle sorting bowl, bottle unscrambling device, and the electrical cabinet .

The machine is suitable for unscrambling polyester bottles and make them in one line, then discharge them by vacuum conveyor, its features are as followed: PLC program controlling, digit show speed, automatic. High speed operation, easy to combine with all kinds of filler or filling production line.

Unscramble the plastic bottles, then transfer them to conveyor in order and certain direction and feed them into other equipment to finish next procedure(such as rinsing hand filling etc), decrease labor intensity and improve productivity effect, also twice polluting caused by hand touching PET bottle.

| Machine Size | Power Supply | Power | Weight | Suitable bottles | Capacity |

| 1650*900*1050MM | AC 220/380V;50/60HZ | 0.3KW | 210KG | customized | ≤8000 BPH |

Reliable, Superior, Unscrambler Equipment

Having a reliable plastic bottle or container unscrambler is essential to maximize efficiencies and assure your containers are prepared for the next step in the packaging process. Using an unscrambler from AMPACK will make certain you have an unscrambler that is easy to understand, easy to operate and maintain, and will also provide years of trouble free production.

AMPACK’s line of high speed bottle unscramblers include low profile, high performance, space saving, heavy duty, and ergonomically designed models that can be easily integrated with existing or new equipment. These unscramblers will automatically take your decorated or virgin bottles from random bulk, and place them firmly without damage on your packaging line conveyor for downstream operations.

How Do Bottle Unscramblers Work

Bottle unscramblers receive the bottles in random positions since containers are thrown randomly into a large hopper that can hold thousands of bottles. Then those bottles are handled in different ways from the hopper to other parts of the machines, so they are sorted until you get a standing bottle directly in your conveyor going to a bottle filler then to a capping machine, labeler and the rest of the filling line.

This is a basic explanation: there are thousands of bottle designs, and each container needs to be analyzed for a bottle unscrambling machine to work correctly, take into consideration, among other things:

Required Speed

Since the bottle unscrambler is at the beginning of the bottling line, it needs to be the fastest machine to make sure that it can catch up with any of the other filling equipment in the line if there is a stoppage.

Container size

Container size in liquid filling machinery is critical for machine size recommendation; for example, a 32 in bowl machine can do 200 + bottles per minute of a 2oz bottle, but it will only do 10-15 bottles per minute on gallons. Also, a 25 cubic foot hopper can accommodate thousands of 2oz bottles so the machine can run for a long time without any operator, but it can only accommodate a few dozen gallons, so the unscrambler could only run for a few minutes before the hopper has to get filled again.

Design features

Each container design feature on a container can present a challenge on any part of the unscrambling process; it can be too soft, ridges that damage the container, dimensionally hard to orient (Bottle diameter and height are similar), guides on the bottle that catch the hook, among other things.

Installation location

A lot of production lines start without a bottle unscrambler, and when analyzing the possibility to add one, there is no good space to place it on a liquid filling line since these machines tend to be on the largest of the production lines. Normally it’s placed before the liquid filler or powder filling machine. Some customers also install the unscrambler machine right before the labeling machine when it’s convenient to label the containers before the liquid filler.

Material

Container material, the possibility of marking and scratching, fragility, quality issues are a few of the challenges we encounter getting our machines to work properly, pet bottles may require special handling to avoid scratches while getting sorted on the PET bottle unscrambler.

Cleaning containers on unscramblers

We offer air rinsing option on our unscramblers but it’s important to note that the cleaning done on this systems with ionized air or ionized air rinsing is minimal, for containers that require cleaning a dedicated bottle rinser is recommended.

Secondary Orienting

To automatically feed containers into a production line, some containers require secondary orienting so the containers are in the right position before going into the liquid filling machines or packaging equipment. Additional orienting is necessary when the bottle coming out of the bottle unscrambler gets delivered into the conveyor in many positions; an example of this would be a motor oil quart with the off-center neck. On a typical bottle unscrambler, the containers will feed these nonsymmetrical containers either neck leading or neck trailing, so to automate the packaging line, you need to add secondary orientation.

Related Products

Essential Oil Filling Machine

Essential Oil Filling Machine 30ml Bottle Filling Machine: The Ultimate Guide

30ml Bottle Filling Machine: The Ultimate Guide How Does A Tube Filling Machine Work?

How Does A Tube Filling Machine Work? Fruit Juice Filling Machine: The Ultimate Guide

Fruit Juice Filling Machine: The Ultimate Guide What Are Equipment Used For Filling?

What Are Equipment Used For Filling? Mango Juice Filling Machine: The Ultimate Guide

Mango Juice Filling Machine: The Ultimate Guide What Is Bottling Line Work?

What Is Bottling Line Work? Ointment Filling Machine

Ointment Filling Machine How Does A Liquid Filling Machine Work?

How Does A Liquid Filling Machine Work? Bottle Capping Machine

Bottle Capping Machine