Introduction

Explanation of Monoblock Filling Machines

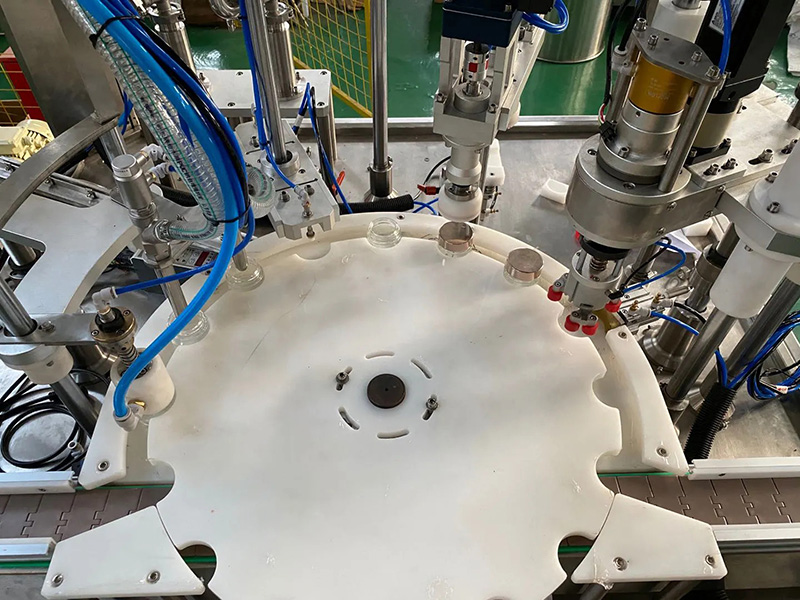

A monoblock filling machine is a complete and integrated system used to fill liquid products into containers. These machines are designed to automate the filling process and improve efficiency, accuracy, and safety compared to manual filling methods. Monoblock filling machines can fill a wide variety of liquids including water, juice, sauces, and more.

Importance of Choosing the Right Monoblock Filling Machine

Choosing the right monoblock filling machine is crucial for the success of your business. The right machine can help you increase efficiency, reduce waste, improve product quality, and enhance safety. On the other hand, the wrong machine can lead to increased downtime, lower productivity, and decreased profitability. That's why it's important to carefully evaluate your business needs and choose a monoblock filling machine that meets your specific requirements.

Benefits of Monoblock Filling Machines

Increased Efficiency

One of the biggest benefits of using a monoblock filling machine is increased efficiency. These machines are designed to automate the filling process, which reduces the time and manual labor required to fill containers. This not only saves time but also reduces the risk of human error and increases the consistency of the fill volume. As a result, you can fill more containers in less time, improving overall productivity and profitability.

Improved Accuracy

Another major benefit of monoblock filling machines is improved accuracy. These machines are equipped with precision metering systems that ensure consistent and accurate fill volumes. This helps reduce waste, improve product quality, and increase customer satisfaction.

Enhanced Safety

Monoblock filling machines are designed with safety in mind. They are equipped with safety features such as automatic shut off valves and emergency stop buttons that help prevent accidents and injuries. These machines also reduce the risk of contamination by eliminating the need for manual handling of containers and liquids.

Lower Maintenance Costs

Monoblock filling machines are built to last, with high-quality materials and durable construction. This results in lower maintenance costs compared to manual filling methods and older, less reliable filling machines. Regular maintenance and cleaning are essential to keep your monoblock filling machine running smoothly and prolong its lifespan.

Increased Flexibility

Monoblock filling machines are highly flexible and can be adapted to fill a wide variety of liquids, container sizes, and fill volumes. This allows you to switch between products quickly and easily, improving overall efficiency and reducing downtime. Whether you're filling small bottles or large drums, a monoblock filling machine can help you meet your business needs.

Latest Technologies in Monoblock Filling Machines

Servo-Driven Technology

One of the latest technologies in monoblock filling machines is servo-driven technology. Servo-driven machines use advanced motors to control the filling process, ensuring precise and accurate fill volumes. This technology also provides greater control over the speed and timing of the filling process, further improving efficiency and accuracy.

Intelligent Control Systems

Another advanced technology in monoblock filling machines is intelligent control systems. These systems use advanced algorithms and sensors to monitor and control the filling process. They can detect and correct any deviations in fill volume, pressure, or speed, helping to maintain consistency and improve accuracy. Some intelligent control systems even have the ability to learn from previous fills and make adjustments automatically, further improving the overall performance of the machine.

Automated Cleaning Systems

Many monoblock filling machines now come equipped with automated cleaning systems. These systems can be programmed to clean the machine after each use or on a set schedule, reducing the risk of contamination and improving the overall hygiene of the machine. Automated cleaning systems also help reduce the time and manual labor required for cleaning, freeing up staff to focus on other tasks.

High-Speed Filling Systems

Finally, high-speed filling systems are another latest technology in monoblock filling machines. These systems are capable of filling containers at high speeds, significantly increasing productivity and efficiency. High-speed filling systems also have the ability to fill containers with greater precision and accuracy, reducing waste and improving product quality.

Key Features to Look for in a Monoblock Filling Machine

Precision Metering Systems

When choosing a monoblock filling machine, it's important to look for precision metering systems. These systems ensure accurate and consistent fill volumes, reducing waste and improving product quality. Look for machines that use servo-driven technology or intelligent control systems for even greater accuracy.

Safety Features

Safety should always be a top priority when choosing a monoblock filling machine. Look for machines with automatic shut off valves, emergency stop buttons, and other safety features that help prevent accidents and injuries.

Flexibility and Adaptability

Choose a monoblock filling machine that is flexible and adaptable to your changing needs. Look for machines that can be easily adjusted to fill different liquids, container sizes, and fill volumes. This will allow you to switch between products quickly and easily, improving overall efficiency and reducing downtime.

Ease of Maintenance and Cleaning

Regular maintenance and cleaning are essential to keep your monoblock filling machine running smoothly. Look for machines that are easy to clean and maintain, with automated cleaning systems and high-quality materials that reduce maintenance costs.

Integration with Other Equipment

If you have other equipment in your production line, such as conveyors or labeling machines, look for a monoblock filling machine that can be easily integrated with this equipment. This will help streamline your production process and improve overall efficiency.

How to Choose the Right Monoblock Filling Machine for Your Business

Determine Your Business Needs:

As discussed in the previous section, it's important to understand your business needs before choosing a monoblock filling machine. This includes evaluating the type of liquid you will be filling, the container sizes you will be using, the fill volumes you require, and your overall production goals.

Consider the Type of Products You Fill:

The type of liquid you will be filling can have a significant impact on the type of monoblock filling machine you choose. Some machines are specifically designed to handle certain types of liquids, such as viscous liquids, while others may not be suitable. Consider the properties of the liquids you will be filling to determine which machine is best suited to your needs.

Look at the Capacity Requirements:

The capacity requirements of your business are another important factor to consider when choosing a monoblock filling machine. Consider the number of containers you will be filling each day and choose a machine that can meet those requirements. It's also important to consider the size of the containers you will be filling, as this can impact the size and type of monoblock filling machine you choose.

Evaluate the Speed and Accuracy Requirements:

The speed and accuracy of your monoblock filling machine will have a significant impact on your overall production efficiency. Consider the fill volumes you require, as well as the speed at which you need to fill containers, and choose a machine that can meet those requirements.

Consider the Space Available:

Finally, consider the space available in your production facility. Monoblock filling machines can be large and complex, so it's important to ensure that you have sufficient space to accommodate the machine and any other equipment you may need. Consider the layout of your facility, as well as any access requirements, to ensure that you choose a machine that can be easily installed and used in your production environment.

Conclusion

In conclusion, a monoblock filling machine is a critical component of many liquid packaging operations. With the right machine, you can improve your production efficiency, reduce waste, and ensure that your products are of the highest quality. When choosing a monoblock filling machine, it's important to consider your business needs, the type of liquid you will be filling, the capacity requirements, the speed and accuracy requirements, and the space available in your production facility. By carefully evaluating these factors, you can choose the right monoblock filling machine for your business and take your production to the next level.