Introduction

Definition of tincture filling machines:

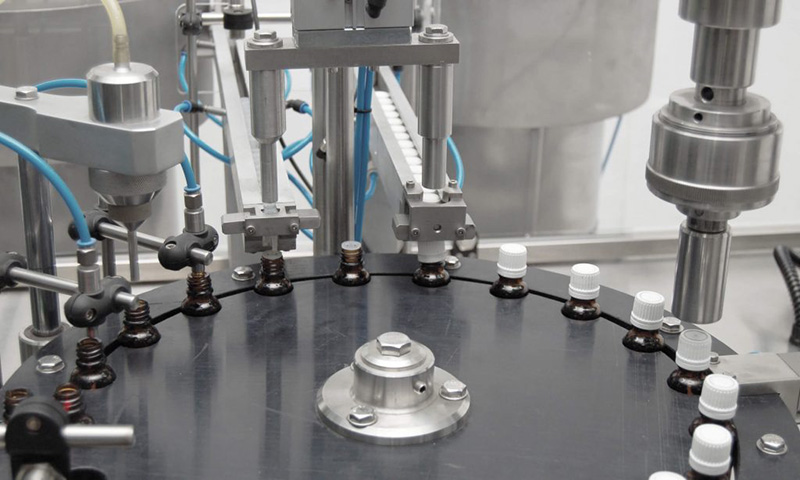

Tincture filling machines are specialized equipment designed to accurately and efficiently fill tinctures into bottles. Tinctures are a popular form of alternative medicine and are commonly used for their medicinal benefits.

Importance of tincture filling machines in packaging industry:

Packaging tinctures into bottles can be a time-consuming and labor-intensive process without the proper equipment. Tincture filling machines streamline this process, making it much easier and more efficient.

Purpose of the guide:

This guide aims to provide a comprehensive understanding of tincture filling machines, including their key features, benefits, and what to look for when choosing the right one for your business. By the end of this guide, you will have a clear understanding of how tincture filling machines can help improve the efficiency and accuracy of your packaging process.

Key Features of Tincture Filling Machines

Precision filling:

Precision filling is crucial when it comes to packaging tinctures, as even small inaccuracies can result in discrepancies in the final product. Tincture filling machines are designed to fill tinctures with precision and accuracy, ensuring consistent and accurate dosing.

Speed:

Tincture filling machines are capable of filling tinctures at a much faster rate than manual methods, allowing you to increase the speed of your packaging process. This increased speed can lead to increased efficiency and improved production times.

Ease of use:

Tincture filling machines are designed to be user-friendly and intuitive, making them easy to use even for those with limited experience. This ease of use minimizes the need for training and reduces the risk of operator error.

Flexibility:

Tincture filling machines come in various sizes and capacities, allowing you to choose the machine that best fits your needs. This flexibility allows you to choose the machine that best fits your specific requirements, whether you are packaging small or large quantities of tinctures.

Versatility:

Tincture filling machines can be used with a variety of bottle sizes and shapes, allowing you to package tinctures into a range of containers. This versatility ensures that you can package tinctures in the container of your choice, regardless of the size or shape.

Benefits of Tincture Filling Machines

Increased efficiency:

Tincture filling machines increase the efficiency of the packaging process, allowing you to package tinctures at a faster rate than manual methods. This increased efficiency can result in higher production rates and reduced labor costs.

Improved accuracy:

Tincture filling machines are designed to fill tinctures with precision and accuracy, reducing the risk of inaccuracies in the final product. This improved accuracy helps ensure consistent and accurate dosing for the consumer.

Reduced labor costs:

The use of tincture filling machines can significantly reduce the need for manual labor, as the machine takes care of the filling process. This reduction in manual labor can result in lower labor costs and improved production times.

Increased capacity:

Tincture filling machines come in various sizes and capacities, allowing you to choose the machine that best fits your needs. This increased capacity can result in higher production rates and improved efficiency.

Enhanced quality:

Tincture filling machines are designed to fill tinctures with precision and accuracy, ensuring consistent and accurate dosing for the consumer. This enhanced quality can result in improved customer satisfaction and a stronger reputation for your business.

Choosing the Right Tincture Filling Machine for Your Business

Determine your needs:

Before choosing a tincture filling machine, it is important to determine your specific needs. Consider the size and shape of the bottles you will be using, the volume of tinctures you will be packaging, and any other specific requirements you may have.

Research available options:

Once you have determined your needs, research the available options for tincture filling machines. Read reviews, compare features, and consider the manufacturer's reputation.

Consider the manufacturer:

The manufacturer of the tincture filling machine is an important consideration, as you want to choose a reputable and reliable manufacturer. Look for a manufacturer with a proven track record of producing high-quality equipment and providing excellent customer support.

Test the machine:

Before making a final decision, it is important to test the tincture filling machine to ensure it meets your needs and provides the level of precision and accuracy you require. Test the machine with the specific bottles and tinctures you will be using to ensure it is the right fit for your business.

By considering these factors, you can choose the right tincture filling machine for your business, ensuring efficient and accurate packaging for your tinctures.

Conclusion

Summary:

In conclusion, tincture filling machines are specialized equipment designed to accurately and efficiently fill tinctures into bottles. They offer numerous benefits, including increased efficiency, improved accuracy, reduced labor costs, and enhanced quality.

Recommendation:

For those in the alternative medicine industry, tincture filling machines are a must-have investment. By choosing the right machine for your business, you can streamline the packaging process, improve accuracy, and provide consistent and accurate dosing for your customers.

Final thoughts:

The use of tincture filling machines is a game-changer for the alternative medicine industry, making the packaging process easier and more efficient. If you are looking to improve the efficiency and accuracy of your packaging process, consider investing in a tincture filling machine.