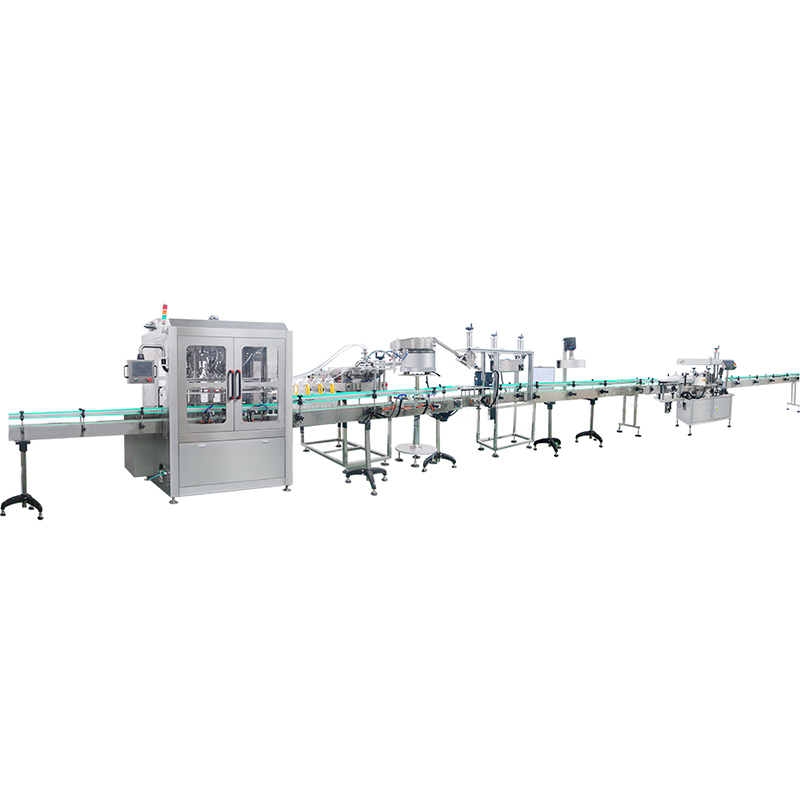

A bottling machine is a machine that is used to package liquids, such as water, soda, beer, and other beverages, into bottles. There are several types of bottling machines, including filling machines, capping machines, labeling machines, and packaging machines. In this article, we will focus on the filling machine, which is the most important part of the bottling process.

The filling machine is responsible for filling the bottles with the liquid product, ensuring that each bottle is filled to the correct volume and with the proper amount of liquid. The filling process begins when empty bottles are placed onto a conveyor belt, which carries them through the filling machine. The bottles are first cleaned and sanitized to ensure that they are free of any contaminants.

Once the bottles are clean and ready to be filled, they are transported to the filling station, where they are positioned under the filling nozzle. The filling nozzle is a tube or spout that dispenses the liquid product into the bottle. The nozzle is typically controlled by a valve or other mechanism that regulates the flow of the liquid.

The filling process begins when the filling nozzle is opened, allowing the liquid product to flow into the bottle. The bottle is usually held in place by a clamp or other mechanism to ensure that it remains stationary during the filling process. The bottle is filled until it reaches the desired volume, which is typically measured using a sensor or other measurement device.

Once the bottle is filled to the correct volume, the filling nozzle is closed, and the bottle is moved to the next station, where it is sealed with a cap or closure. The cap is typically applied using a capping machine, which uses a series of rollers or other mechanical devices to secure the cap onto the bottle.

After the cap is applied, the bottle is labeled with information such as the brand name, product name, and expiration date. This is typically done using a labeling machine, which prints the labels and applies them to the bottles. The labeled bottles are then inspected to ensure that the labels are properly applied and legible.

Finally, the bottled product is packaged for shipping or storage. This is typically done using a packaging machine, which places the bottles into boxes or other containers and seals them for transport.

Overall, the bottling process is a complex and highly automated process that involves several different machines and processes. Bottling machines are designed to be efficient, accurate, and reliable, ensuring that the bottled product is of high quality and meets the necessary standards for safety and purity.

There are many different types of bottling machines available, each designed for a specific purpose or application. Some common types of bottling machines include:

- Filling machines: These machines are responsible for filling the bottles with the liquid product. There are many different types of filling machines available, including gravity fillers, pressure fillers, and volumetric fillers. Gravity fillers use the force of gravity to fill the bottles, while pressure fillers use pressurized air or gas to force the liquid into the bottle. Volumetric fillers use a metering device to dispense the exact amount of liquid required.

- Capping machines: These machines apply caps or closures to the bottles to seal them. Capping machines can be manual or automatic, and they use a variety of techniques to apply the caps, such as screwing, crimping, or snapping.

- Labeling machines: These machines apply labels to the bottles, which can include information such as the brand name, product name, and expiration date. Labeling machines can be manual or automatic, and they use a variety of techniques to apply the labels, such as adhesive, heat transfer, or inkjet printing.

- Packaging machines: These machines package the bottled product for shipping or storage. Packaging machines can be manual or automatic, and they use a variety of techniques to package the bottles, such as placing them in boxes or cases, wrapping them in plastic or paper, or sealing them in bags or pouches.

In addition to these basic types of bottling machines, there are also many specialized machines and equipment that can be used in the bottling process, depending on the specific needs of the product and the production environment. Some common examples include conveyor belts, bottle washers, sterilizers, and inspection systems.

The bottling process can be further automated and streamlined using advanced technologies such as robotics and computerized control systems. These technologies can help to improve the accuracy and efficiency of the bottling process, as well as reduce the risk of errors and accidents.

Overall, the bottling process is a critical part of the production and distribution of many different types of liquid products. Bottling machines play a vital role in this process, ensuring that the product is properly packaged and labeled, and ready for distribution to customers.