A commercial bottling machine is a piece of equipment that is used to package and seal liquids, such as beverages, into bottles or containers. These machines are commonly used in the food and beverage industry to package products like soda, beer, water, and juice. They are also used in the pharmaceutical and chemical industries to package liquids and other products.

There are several different types of commercial bottling machines available, each with its own unique features and capabilities. Some common types of bottling machines include:

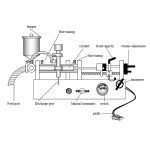

- Filling machines: These machines are used to fill bottles or containers with a specific volume of liquid. They can be gravity-fed or use pressure to fill the bottles.

- Capping machines: These machines are used to seal the bottles or containers after they have been filled. There are several different types of capping machines, including screw cappers, snap cappers, and spindle cappers.

- Labeling machines: These machines are used to apply labels to the bottles or containers. They can be manual or automated, and can apply labels to the front, back, or sides of the bottles.

- Packaging machines: These machines are used to package the bottles or containers into cases or other packaging materials. They can be manual or automated, and can be used to package a variety of different products.

When choosing a commercial bottling machine, it is important to consider the type of product you will be bottling, the volume of production, and the specific requirements of your business. Some other factors to consider include:

- Speed and efficiency: How quickly does the machine operate, and how many bottles or containers can it process per minute?

- Accuracy: Can the machine accurately fill the bottles or containers to the desired volume?

- Safety: Is the machine safe to use, and does it have any safety features in place to protect the operator?

- Maintenance and upkeep: How easy is it to clean and maintain the machine, and what kind of ongoing maintenance is required?

- Cost: What is the initial cost of the machine, and what are the ongoing costs for maintenance and repairs?

There are several different brands and models of commercial bottling machines available, each with its own unique features and capabilities. Some popular brands include Krones, Sidel, and KHS.

When purchasing a commercial bottling machine, it is important to do your research and compare the different options available. Some things to consider when comparing different machines include:

- Production capacity: How many bottles or containers can the machine process per minute, and does it meet the production needs of your business?

- Features and capabilities: Does the machine have the specific features and capabilities that your business requires, such as labeling or packaging capabilities?

- Ease of use: Is the machine easy to operate and maintain, and does it come with training or support for the operator?

- Cost: What is the initial cost of the machine, and what are the ongoing costs for maintenance and repairs?

- Warranty and support: Does the machine come with a warranty, and is there a network of support available if something goes wrong or if you have questions?

In addition to purchasing a commercial bottling machine, there are also several other considerations to keep in mind when setting up a bottling operation. These include:

- Quality control: It is important to have a system in place to ensure that the products being bottled are of high quality and meet all relevant safety standards. This may include testing the products at various stages of the bottling process, as well as implementing quality control measures such as sterilization and pasteurization.

- Packaging materials: In addition to the bottling machine, you will also need to purchase packaging materials such as bottles, caps, labels, and cases. It is important to choose packaging materials that are suitable for your specific product and meet any relevant safety standards.

- Production planning: It is important to have a production plan in place to ensure that the bottling process runs smoothly and efficiently. This may include scheduling production times, organizing raw materials and packaging materials, and coordinating the different stages of the bottling process.

- Labor and training: You will need to hire and train employees to operate the bottling machine and handle other tasks such as quality control, packaging, and labeling. It is important to choose skilled and reliable employees who are trained in the proper use of the equipment and safety procedures.

- Maintenance and upkeep: Proper maintenance and upkeep of the bottling machine is crucial to ensure its continued operation and longevity. This may include regular cleaning and maintenance, as well as repairs and replacements as needed.

In conclusion, a commercial bottling machine is a valuable piece of equipment for businesses that produce and package liquids such as beverages, pharmaceuticals, and chemicals. There are several different types of bottling machines available, and it is important to choose the one that best meets the needs and requirements of your business. Other considerations when setting up a bottling operation include quality control, packaging materials, production planning, labor and training, and maintenance and upkeep. By taking the time to carefully consider these factors and make informed decisions, you can ensure the success and efficiency of your bottling operation.