A 6 head filling machine is a type of liquid filling equipment that is used to dispense precise amounts of liquids into containers or bottles. These machines are typically used in the food, beverage, pharmaceutical, and cosmetics industries to efficiently and accurately fill containers with products such as sauces, juices, oils, and lotions. In this ultimate guide, we will explore the various features and capabilities of a 6 head filling machine, as well as the benefits and considerations when using this type of equipment.

Introduction to 6 head filling machines

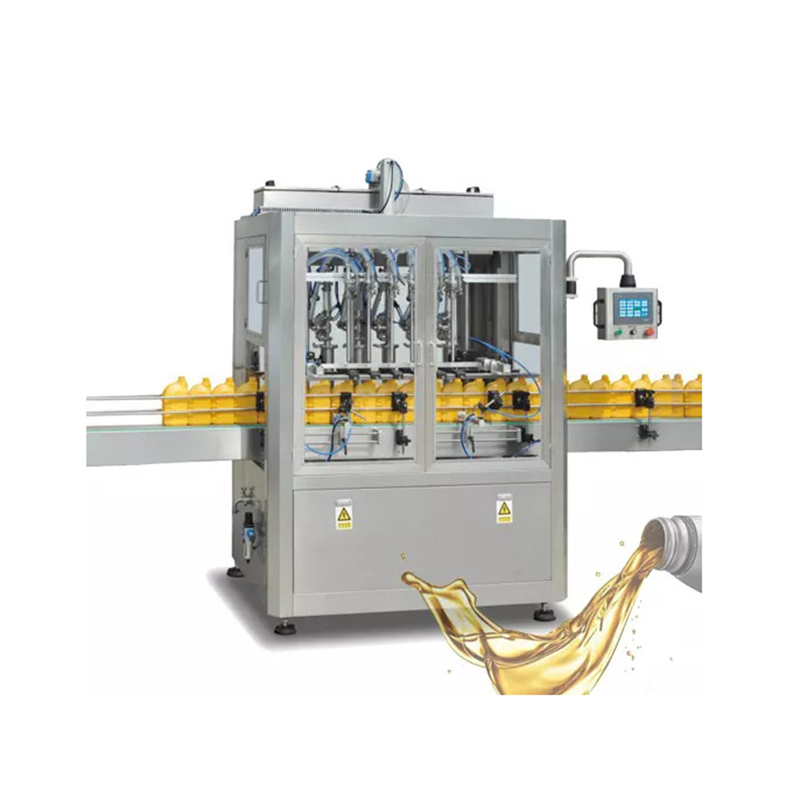

A 6 head filling machine is a type of automatic filling machine that utilizes multiple filling nozzles or heads to dispense liquid products into containers. These machines are designed to handle a variety of container sizes and shapes, as well as a range of liquid viscosities and filling volumes. 6 head filling machines are typically used in high-volume production environments where speed and accuracy are crucial.

Types of 6 head filling machines

There are several types of 6 head filling machines available on the market, each designed for specific applications and industries. Some common types of 6 head filling machines include:

Gravity filling machines:

Gravity filling machines use the force of gravity to dispense liquids into containers. These machines are suitable for low to medium viscosity products and are typically used for filling containers with products such as water, juices, and wines.

Piston filling machines:

Piston filling machines use a reciprocating piston to dispense liquids into containers. These machines are suitable for medium to high viscosity products and are typically used for filling containers with products such as sauces, creams, and gels.

Volumetric filling machines:

Volumetric filling machines dispense liquids into containers based on volume measurement. These machines are suitable for a wide range of viscosities and are typically used for filling containers with products such as oils, syrups, and personal care products.

Net weight filling machines:

Net weight filling machines dispense liquids into containers based on weight measurement. These machines are suitable for a wide range of viscosities and are typically used for filling containers with products such as food products, chemicals, and personal care products.

Features and capabilities of 6 head filling machines

6 head filling machines are equipped with a range of features and capabilities to ensure accurate and efficient filling of liquid products. Some common features and capabilities of 6 head filling machines include:

Multiple filling nozzles or heads:

As the name suggests, a 6 head filling machine is equipped with six filling nozzles or heads, allowing for faster filling speeds and higher production rates.

Adjustable filling volumes:

Most 6 head filling machines allow for the adjustment of filling volumes, enabling the user to dispense precise amounts of liquids into containers.

Container handling:

6 head filling machines are designed to handle a variety of container sizes and shapes, including bottles, jars, pouches, and tubes.

Product handling:

6 head filling machines can handle a range of liquid viscosities, from thin liquids such as water and juice to thick liquids such as sauces and creams.

Control panel:

6 head filling machines are equipped with a control panel, which allows the user to set filling parameters, start and stop the machine, and monitor the filling process.

Benefits of using a 6 head filling machine

There are several benefits to using a 6 head filling machine for liquid filling applications. Some of the main benefits include:

Increased production rates:

6 head filling machines are capable of filling containers at high speeds, allowing for increased production rates and reduced downtime.

Improved accuracy:

6 head filling machines are designed to dispense precise amounts of liquids into containers, ensuring that products are accurately filled to the desired volume or weight. This can help to reduce waste and improve product quality.

Greater efficiency:

6 head filling machines are highly efficient, with the ability to fill multiple containers simultaneously. This can help to reduce labor costs and improve overall productivity.

Enhanced safety:

6 head filling machines are equipped with safety features such as emergency stop buttons and safety guards, ensuring the safety of operators and preventing accidents.

Considerations when using a 6 head filling machine

While 6 head filling machines offer many benefits, there are a few considerations to keep in mind when using this type of equipment. Some things to consider include:

Cost:

6 head filling machines are typically more expensive than smaller, single head filling machines. This is due to the additional complexity and features of the equipment.

Maintenance:

6 head filling machines require regular maintenance to ensure optimal performance and longevity. This can include cleaning and lubrication of the filling nozzles, as well as periodic checks and repairs.

Product compatibility:

It is important to ensure that the 6 head filling machine is compatible with the specific liquid product being filled. This includes factors such as viscosity, pH level, and the presence of particulates.

Operator training:

Proper operator training is essential to ensure the safe and effective use of a 6 head filling machine. This includes training on the machine's controls, safety features, and maintenance procedures.

Conclusion

A 6 head filling machine is a highly efficient and accurate piece of equipment that is essential for many liquid filling applications. These machines are capable of filling a variety of container sizes and shapes with a range of liquid viscosities at high speeds. While there are considerations to keep in mind when using a 6 head filling machine, the benefits of increased production rates, improved accuracy, and enhanced safety make it a valuable investment for many businesses.